Red seabream, Pagrus major (Temminck and Schlegel, 1843) is a demersal species that occurs in the northwest Pacific (the northeastern part of the South China Sea northward towards Japan) at depths between 10 and 50 m. The red sea bream, Pagrus major (Chrysophrys major), is the most valuable marine fish in Japan. It is high-priced in Japan and used in various occasions such as wedding and festival. It is also used in some Chinese medicine. A first trial to culture it has been made at a hatchery located at Seto Inland Sea coast in 1902 (KAJIYAMA, 1937). The hatchery was soon closed because of difficulty in rearing the larvae. Since 1960, the culture of the young yellow-tail, the culture of the red sea bream did not progress until 1970. Basic research on larval production has been carried out at the universities since 1955. KASAHARA, HlRANO and OSHIMA (Japanese scientists) succeeded in rearing the larval stage of black sea bream, Mylioma aroaephalus, in 1959 (KASAHARA et al., 1960). SHlKAMA, Y~MASHITA and NISHIZUKA succeeded in rearing 22 red sea bream fry from the eggs for the first time in Japan in 1962 (YAMASHITA, 1967). These successes were achieved on an experimental scale, and therefore, further experimentation was necessary before developing mass production methods.

In 1964, KITTAKA showed effectiveness in larval production with large scale outdoor concrete tanks. He developed a method for mixed cultures of larvae and suitable food organisms in 200 m3 tanks (HUDINAGA and KITTAKA, 1967). In 1967, NOGUCHI observed natural spawning' of cultured red sea breams in a large tank at Naruto Aquarium, Tokushima, Japan+ (NOGUCHI, 1968). Based on these successes, research has been carried out in order to find a mass rearing method for red sea bream larvae at the hatcheries belonging to Seto Inland Sea Fish Farming Association (ANONYMOUS, 1974). Most sparid species have been used in mariculture and cultivated in cages.

CLASSIFICATION AND CHARACTERS

Kingdom: Animalia (animals)

Phylum: Chordata (chordates)

Subphylum: Vertebrata (vertebrates)

Superclass: Gnathostomata (jawed vertebrates)

Class: Actinopterygii (ray-finned fishes)

Order: Perciformes

Family: Sparidae

Genus: Pagrus

Species: Pagrus major

The family Sparidae contains 35 genera and 112 species, distributed mainly in tropical and temperate waters of the Atlantic, Pacific and Indian oceans (Froese and Pauly, 2005). Eighteen of these species inhabit the Adriatic continental shelf (Jardas, 1996). Two of these belong to the genus Pagrus (Cuvier, 1816): Pagrus pagrus (Linnaeus, 1758) and Pagrus coeruleostictus (Valenciennes, 1830).

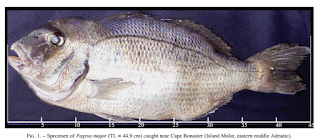

DISCRIPTION

Body robust, oblong, moderately compressed. Upper profile of head convex with a bulge above eye. Lower jaw slightly shorter then upper. Head and upper body dark violet, sides and belly silvery. Several small bright blue spots on upper sides. All spines of dorsal fin tough and not elongated. Caudal fin forked with pointed lobes. Scales moderately large, absent from bases of soft dorsal and anal fins. Posterior margin of caudal fin black, lower margin white.

Dorsal spines (total): 12; Dorsal soft rays (total): 10; Anal spines: 3; Anal soft rays: 8. Body with many bluish dots when fresh. Shallow body, body depth 2 or more in SL. Transverse scales 6.5-7.5. All spines of dorsal fin are tough and not elongated. Posterior margin of caudal fin black, lower margin is white. Occurs from 10 to 50 m depths, often on rough grounds, but also on softer bottoms. Also inhabits reefs Adults migrate into shallower parts of their depth range to spawn in late spring and summer; juveniles occur mainly in the shallower areas. It is a popular food fish throughout its range. Feeds on benthic invertebrates, including echinoderms, worms, mollusks and crustaceans; also on fishes. The fishes are also cultivated in cages.

NATURAL DISTRIBUTION

They are mainly distributed in Northwest Pacific: northeastern part of South China Sea (Philippines excluded) northward to Japan.

Hatchery Design

The basic considerations in establishing a fish hatchery are: (i) which site is suitable, (ii) what is the area of the site and the facilities required in relation to the goals or objectives of the hatchery, and (iii) how will the hatchery be managed.

It is of primary importance to conduct a feasibility study to determine the suitability of the site. This should be done prior to the establishment of the hatchery. There are three factors which must be considered in designing a fish hatchery: (i) species, (ii) production target, and (iii) level of financial input. In addition, the facility requirements will depend on the nature of organization to run the hatchery. For government pilot projects, some laboratory support facilities are required. Otherwise, it may not be necessary as in commercial projects.

The design of the hatchery will also depend on its objectives. Experimental facilities or production-oriented system for commercial purposes or the combination of both may be incorporated in the design.

The hatchery can be an independent enterprise which is entirely self-sufficient in terms of facilities and manpower or as part of a bigger organization which utilizes its facilities and technical know-how. The hatchery can be an independent enterprise by itself or vertically integrated with other aquaculture enterprises in an organization.

Criteria in the selection of sites for seabream hatchery

1 Seawater supply

The seawater used in a hatchery should be clean, clear and relatively free from silt. The water quality should be good with minimal fluctuation in salinity all year round. Suitable sites are usually found near sandy or rocky shore. Sites which are not suitable for hatchery include areas which are heavily influenced by rain or turbulence. River mouths should be avoided as abrupt salinity change occurs after a heavy rainfall. An added advantage of having a site on rocky shores is that good quality seawater is relatively near the shoreline. This reduces the cost of piping installation and pumping. The hatchery site should also be free from any inland water discharges containing agricultural or industrial wastes.

2. Accessibility

Ideally, a hatchery site should be selected in areas where there are active fish farming operations so that the fish larvae produced can be easily transported and distributed to the grow-out ponds and cages. The site chosen for a hatchery must have easy access to communication and transportation channels.

3. Availability of power source

A fish hatchery cannot be operated without electricity. Electricity is essential to provide the necessary power to run the equipment and other life support systems of the hatchery. Hence, the site must have a reliable source of power. Installation of a standby generator is absolutely necessary especially in areas where there are frequent and/or lengthy power failures and fluctuations.

4 Topography

The ideal site should be spacious, situated on flat to gently sloping grounds, well drained and not susceptible to floods, strong wave and tidal actions. It should also be on compact soil and accessible by paved road.

5 Acquisition

It is advisable to pay attention to land values early in the site selection phase to ensure that the site is available for purchase or lease and at a price consistent with the project budget. Since land with the above characteristics is generally also desirable for other activities, it may be competitive for alternate land usage.

Hatchery size

Hatchery design is aimed at achieving certain production targets which in turn determine the size of the hatchery. The capacity is based on an approximate ratio between tank for production of natural food (algae and rotifer) and larval rearing tank. The spawning tank depends on the larval requirement which is based on the number of spawners.

Holding tanks

The holding tanks in the seabream hatchery are used for various purposes such as for brood stock conditioning and subsequent spawning, incubation, larval rearing and production of natural food.

Seawater system

Seawater can be drawn directly from the sea or from the sump pit. If the source of water is relatively clear, the water can be pumped directly into the overhead filter tank and stored in the reservoir or storage tank. Water is then gravity-fed to various culture tanks through delivery pipes. However, if the water is turbid and contains a high concentration of suspended solids, it must be pumped first into a sedimentation tank where the suspended solids are allowed to settle down. Only the clear upper portion water is pumped into the filter tank. In some areas where water source is far from the shoreline and during low tide where large quantity of water is needed continuously, the sump pit or tube well can be constructed inshore near the hatchery. The sumps pit is connected to an underground pipe which is situated towards the water source. The water continuously enter the sump pit through the underground pipe even during low tide. Water is then pumped directly from the sump pit or tube well. Water from the sump pit or tube well is usually clear because the water is filtered naturally through a layer of sand before entering the pipe so that it can be used directly. However, if vary clear and clean water is required, it should be pumped through the filter tank before use.

A larval rearing tank.

SPAWNING AND HATCHING.

Maturation

The red sea breams used for spawning are kept in net cages or concrete tanks

(Dimensions: 10-20 m x 10 m x 5 m), for about a year or two depending on their initial ages. The red sea bream becomes sexually mature when 3 years old. Its feeding activity is dependent on temperature. Breeders are cultured in the southern part of Japan during winter. The spawning season extends from April to June, with a peak in early May.

Brood stock development

There are two sources of seabream brood stock: wild-caught adults and from ponds/cages (2–6 years old fishes averaging in weight from 3 to 5 kg). It is advantageous to use pond or cage-reared brood stock as they are already used to culture conditions being easier to condition and develop them into broodfish. However, when 2–3 year old cultured stocks are not available, wild-caught adults can be used, but they must be first acclimatized under cage or pond condition for at least 6 months before being used as spawners.

1. Wild brood stock collection

The fishery worker must constantly strive to minimize stress in handling captive brood stock. Efforts to capture seabream should be confined to areas where they are known to occur. The selection of a suitable gear or method of capture must also be considered. Unless the fish are abundant in an area, the effort and cost required for capturing fish will become astronomical.

2. Conditioning of wild brood stock

Captured fish are placed immediately in transport tanks and taken directly to the hatchery or holding cages. Anesthetic is not necessary if the fish are shipped in live tanks or in aerated transport containers. Upon arrival at the hatchery, the fish are treated with antibiotic such as oxytetracycline. If antibiotic is applied directly into the water, absorption is effected across the gills and the skin of the fish. The recommended concentrations of antibiotics are: 2 ppm for the dripping method for 24 hours and 20 mg per 1 kilogram of fish for the injection method.

In nature, seabream is a carnivorous and feeds voraciously on live fish. However, in captivity, they can be conditioned to feed on dead fish. After recovery from initial injuries resulting from capture, seabream can be trained to feed on fresh marine fish. It often takes a few days before the fish gets used to the new diet. It is important to throw the feed piece by piece as the seabream never eat the food when it settles to the bottom of the tank. The uneaten feed should be removed to prevent water pollution.

3. Brood stock maintenance

The fish, whether cultivated or wild-caught, can be maintained as brood stock in cages and concrete tanks.

(a) Cages

Floating cages are usually used for brood stock development. Cages made of polyethylene netting materials are attached to GI pipe or wooden frames kept afloat by Styrofoam drum and anchored within a calm bay or sheltered marine environment .The size of the cages varies from 10 to 100 sq.m in surface area with a depth of 2 meters (dimension: 5 × 5 × 2m or 10 × 10 × 2m). Smaller cages are more suitable because they are easier to maintain and manage (such as in changing of net and harvesting). The mesh size of a brood stock cage varies from 4–8 cm. Stocking density of fish is 1 per cubic meter of water.

(b) Concrete tanks

The size of concrete tanks used for holding brood stock depends on the size of the hatchery. It is advisable to use a bigger tank to allow the fish ample space for swimming. Generally, tank volume ranges from 100–200 tons (5 × 10 × 2m and 10 × 10 × 2m). Stocking rate in brood stock tank is 1 fish for every 2 cubic meters of water. Good water quality in brood stock tanks should be maintained. A water change of about 30–50% daily is recommended.

Spawning and fertilization

1. Selection of spawners

The selection of spawners from the brood stock should be done months before the beginning of natural spawning to allow ample time for the fish to be conditioned to environmental and diet controls. Spawners are normally selected based on the following criteria:

- fish should be active

- fins and scales should be complete

- free from disease and parasite

- free from injury or wounds

- males and females of similar size groups are preferred

- spawner should be at least 4–5 kg in body weight and should not be less than 3 years old

Selected spawners are then transferred to the pre-spawning tank. The ratio of male and female stocked in the pre-spawning tank is 1:1.

2 Care of spawners in pre-spawning tank

Immediately after stocking in the pre-spawning tank, the feeding is reduced from 5% to 1% of the total body weight and fed once a day. This is to prevent the fish from getting fat which can result in poor gonadal development. The feed given should be fresh marine fishes such as sardine, yellow stripe thread fin, etc.

Water in the spawning tank should be maintained in good condition. This can be achieved by changing the water about 50–60% daily.

Spawning of seabream

Presently, there are two major techniques employed in mass production of seabream fry in Southeast Asian countries: artificial fertilization and induced spawning.

1 Artificial fertilization.

Spawners are caught in natural spawning grounds near the mouth of the river or in salt water lakes, where the water depth is about 10–20m. Gill net and seine net are commonly used. Normally, the fishermen will net the fish during spring tide 2–3 days before the new moon or full moon until 5–6 days after the new moon or full moon at about 1800–2200 hours, at the time of the rising tide.

The degree of maturity of the collected spawners should be immediately checked. If the female has ripe eggs and the male is in the running stage, stripping is done in the boat. The fertilized eggs can then be transported to the hatchery for subsequent hatching. In cases where only the male is caught, the milt is collected by stripping into a dry glass container. Milt is then stored in an ice box or refrigerator. The milt can maintain its viability after a week in cold storage (5–15°C). The preserved milt should be made available for immediate use when a ripe female is caught.

The dry method of fertilization is normally used in this case. The eggs are stripped directly from the female to a dry and clean container where the milt is added. A feather is used in mixing the milt and eggs for about 5 minutes. Filtered seawater is then added into the mixture while stirring it and then allowed to stand undisturbed for 5 minutes.

2. Induced spawning

Two methods are normally used for inducing seabream to spawn in captivity, e.g. hormonal injection and environmental manipulation. Both methods would induce the fish to spawn naturally in the tank. This results in a monthly spawning until the gonads are spent.

2.1, Induced spawning by hormone injection

After stocking seabream brood stock in the pre-spawning tank for two months, the fish are inspected twice a month during spring tide, ovarian maturity of the female is measured as follows: the eggs are sampled from the female through the use of a polyethylene cannula of 1.2 mm in diameter. The fish is either anaesthetized or inverted gently with a black hood over the head. The cannula is inserted into the oviduct for a distance of 6–7- cm from the cloaca. Eggs are sucked orally into the tube by the operator as the cannula is withdrawn. The eggs are then removed from the cannula and egg diameter measurement is made. When the seabream eggs reach the tertiary yolk globule stage or have a diameter of 0.4–0.5 mm, the female is ready for hormone injection. In males, only those with running milt are chosen.

The hormones usually used to induce spawning in seabream that produce reliable results are:

- Puberogen

- HCG + pituitary gland of Chinese carp

Puberogen consists of 63% follicle stimulating hormone (FSH) and 34% Leutinizing hormone (LH). The dosage usually applied is 50–200 IU/kg of fish. The fish will spawn at about 36 hours after injection. If no spawning occurs, the second injection is applied 48 hours after the first injection. The dosages of second injection should be double from that of the first injection and can also be given 24 hours after the initial injection. The male is usually injected at the same time as the female with a dosage of 20–50 IU/kg of fish. The fish will normally spawn within 12–15 hours after the second injection.

Homogenized pituitary glands of Chinese carp are used at 2–3 mg/kg of fish mixed with Human Chorionic Gonadotropin (HCG) at 250–1,000 IU/kg of fish. The time interval of application and spawning are the same when using puberogen .

Before injection, the spawner should be weighed and the hormone requirement computed. Spawners should be injected intramuscularly below the dorsal fin. After injection, they should be transferred from pre-spawning tank to the spawning tank. Twenty four hours after first injection, response of the fish to the hormone treatment is often manifested by the swelling of the belly. If the fish is expected to spawn within the next 12–15 hours, a milky white scum (fatty in texture) will appear on the water surface of the spawning tank. If not, a second injection should be given.

Seabream that are induced to spawn by hormone treatment will always spawn within 12 hours after the second injection. The schedule of injections for subsequent spawning must be synchronized with the natural spawning time of the fish which occurs in late evening between 1800 to 2000 hours.

2.2 Induced spawning by environmental manipulation

Based on field observations and analysis of natural phenomena that occur during spawning period of seabream, techniques were developed to stimulate the fish to spawn in captivity. The following steps are necessary:

- changing the water salinity to simulate fish migration

- decreasing the water temperature to simulate the decreased water temperature after rain

- lowering and subsequent addition of fresh seawater to the tank in order to simulate the rising tide, and

- Follow the moon phase.

Initially, the salinity of water in pre-spawning tank is prepared at 20–25 ppt before stocking the selected spawners. After stocking, 50–60% of water is changed daily until 30–32 ppt is reached. This will take about 2 weeks. This will simulate the migration of fish from its growing grounds to the spawning grounds.

Constant monitoring of fish is required to detect pre-spawning behavior. When the fish is observed to display its silver belly, this is an indication that it is ready to spawn.

The female fish separate from the school and cease to feed one week prior to spawning. Two or three days before the new moon or full moon, as the female approaches full maturity, there is an increase in play activity. The ripe male and female swim together more frequently near the surface as spawning time approaches.

At the beginning of the new moon or full moon, the water temperature in the spawning tank is manipulated by reducing the water level in the tank to 30 cm deep at noon time and exposing to the sun for 2–3 hours. This procedure increases water temperature in the spawning tank to 31–32°C. Filtered seawater is then rapidly added to the tank to simulate the rising tide. In effect, the water temperature is drastically decreased to 27–28°C.

The fish spawn immediately the night after manipulation (1800–2000 hours) or if no spawning occurs, manipulation is repeated for 2–3 more days, until spawning is achieved.

Whether the fish is induced by hormone treatment or environmentally manipulated to spawn, they would continue to spawn for 3–5 days after the first spawning provided the environmental factors that stimulate spawning are present, e.g. new or full moon, changes in salinity and temperature, etc. Since seabream spawn intermittently (by batch), the same spawner will continue to spawn during full moon or new moon for the next 5 to 6 months.

Egg collection and incubation

Fertilized eggs of seabream range in size from 0.8–1 mm. They float in the water column (pelagic) and are very transparent.

Eggs in spawning tank can be collected and transferred to incubation tanks by either of the following procedures:

a. The spawning tanks are supplied with continuous flow of seawater. The overflowing water carry the eggs into a small tank (2 × 0.4 × 0.3 m) containing a plankton net (200μ mesh). This is usually set in the afternoon. Seawater should start to flow after the fish have spawned. Eggs are collected and transferred to larval rearing tanks the following morning.

b. The eggs are collected from the spawning tanks using a fine mesh (200μ) seine net the morning after spawning.

The collected eggs should be washed repeatedly through a series of filter screens to remove debris (organic detritus, plankton, etc.) that have adhered to the eggs. The eggs are then placed in graduated cylinders for density estimation. Normally, fertilized eggs float while the unfertilized eggs settle to the bottom of the container. Unfertilized eggs are later removed by siphoning.

Fertilized eggs are then transferred to incubation tank at the density of 100 eggs/liter. The eggs will hatch at about 17–18 hours at 26–28°C after spawning. Dead eggs which settled at the bottom are removed by siphoning. The newly-hatched larvae are carefully collected the following morning by scooping them with a beaker and immediately transferred to larval rearing tanks.

Hatching rate of seabream eggs by environmental and hormonal manipulation ranges between 40–85% and 0.1–85%, respectively.

Larval rearing

The rearing tanks are commonly fabricated from plastic, fiberglass, wood or concrete. A typical larval rearing tank is rectangular in shape and located outdoor. Its volume ranges from 8–10 tons (7 × 1.2 × 1m or 10 × 1.5 × 1m). The tanks are usually protected from strong sunshine and heavy rains by a roof tile cover. The usual stocking density for newly-hatched larvae in rearing tank is between 50–100 larvae/liter.

Egg collecting by seine net.

REARING THE LARVAE

Prelarval stage

The newly hatched larvae are introduced into floating tanks (dimensions: about

2-4 m x 2-4 m x 1.5-2 m) made of synthetic fiber cloths. The floating tanks are hanged in a large concrete tank (water volume: 50-200 m3). The survival rates of pre larvae are improved in tanks with abundant propagation of uni-cellular green algae. In order to promote the propagation of uni-cellular green algae, small amounts of inorganic and organic nutrients are added into the floating tank. The optimum density of uni-cellular green algae is about 300,000 cells/ml. Slight aeration is provided by about 8 vinyl hoses (diameter: 5 mm) per floating tank.

The pre larvae are released into large concrete tanks after they have been reared for about 10 days in the floating tanks. Fertilization is also necessary in most cases.

However, in case of remarkably dense propagation of uni-cellular green algae, the illumination is reduced by covering the top of the tanks and water is exchanged for fresh sea water. Aeration is provided by about 30 vinyl hoses per concrete tank. The daily rate of water renewal is set to 1/4 of the total volume several days before transferring the larvae to another rearing net cage. Waste accumulated on the bottom is removed by siphoning. The newly hatched larvae live for the initial 3 days on their yolk sac. The actual feeding begins on the 4th day after hatching, when the yolk sac is resorbed and the digestive organ is formed. Oyster eggs, rotifers (Braahionus pliaatilis), copepods collected by net, and nauplius of Artemia salina are used for feeding individuals in pre larval stage. The food value of copepods and Artemia was compared. Survival rate of larvae during the period from 23rd to 34th day after hatching was 50 % with copepods and 15 % with Artemia. Thus copepods seem to be a better food than Artemia. However the species and amount of copepods vary depending on location and season. It will be necessary to establish mass culture method of copepods. Maximum initial density of pre larvae was 25000/m3 while the density at harvest was 2000/m3.Average survival rate at pre larval stage was 10 % Pre larvae hatch at 2.0-2.3 mm total length. They grow to about 6 mm total length in 20days.

POST LARVAL STAGE

Post larvae of red sea bream (about 6 mm in total length) are transferred into net cages installed at sea. The water depth of the large concrete tanks is decreased to 1/3 (water volume: 50 m3) before gathering the larvae in order to avoid injury due to water current. A hose (diameter: 5 cm) is connected to the drain. The water flow of the drain is regulated to about 3-5 m3 per hour. Gathering is done from the evening to midnight. The mortality during transfer is about 10 %. It is higher for smaller size post larvae. However the post larvae begin to swim against the water current when 10 mm total length and mortality increases again at this stage. Therefore it is recommendable to transfer the post larvae when 10mm total length.

Four.net cages (dimensions: 3. x 3 m x 2 m) are hanged per raft (dimensions:

8. X 8 m). Mesh of the net is 0.16 cm. The nets are cleaned every 2-3 days and replaced every 5 to 10 days. Post larvae are cultured to fry stage (20-30 mm total length) in the net cages for about l0-40days. Initial density of post larvae in the net cages is about 2.000/m3. The number of fry harvested is about 400-500/m3. Survival rate during net cage stage is about 30 %. Survival rate of fry from hatching to 20 mm total length is about 3 %. Feeding with Braohionus plieatilis and Artemia salina is preferable at the early stage of the net cages. But the main feed used during the net cage stage is trash shrimp and fish flesh.

LARGE SCALE PRODUCTION METHOD

As long as the scale and the method of producing red sea bream larvae are limited to the above mentioned level, the mass production of larvae in the true sense will be difficult to achieve. It was considered that the larvae of red sea bream are sensitive to the change of the environmental conditions. Therefore, rearing of the larvae was carried out in outdoor tanks using filtered sea water. However, many experiments have shown that the larvae can be reared successfully in outdoor tanks using regular sea water.

An interesting experiment was carried out in an outdoor pond at Tamano in 1973.

Post larvae of red sea bream of total length 6-8 mm were released into a nursery pond (area about 500 m2, volume: 400 m3, and depth: about 0.8 m). Prior to the release, fertilization was applied with about 100 kg chicken manure and 30 kg soy sauce waste. Zooplankton, such as copepods, brachyuran larvae, ostracoda, polychaeta larvae and Gammarus were propagated into the pond. In order to avoid a temperature increase, water was exchanged at rates of 1/8oftotal volume daily and 1/4 nightly. The initial number of post larvae released into the pond was

25,800. After 25 days, 4,013 fry were harvested. Survival rate was 16 %. The average total length of the larvae, at the beginning and at harvest was 8.5and 44.5 mm, respectively. Although the survival rate was not so much improved, the growth rate was much better than with net cages.

At present, several thousands of m2 ponds are constructed with dikes in former salt fields, and the newly hatched larvae are released directly into the, ponds, whose water is fertilized. The larvae grow to a size of 20 mm total length in about 35 days. By using this method, it becomes possible to produce several hundred thousands of fry per pond per operation.

The factors affecting the hatching rate

Water temperature:

The fertilized eggs cease to develop at morula stage at 10° C. The hatching rate

Becomes poorer and mortality increases at 25° C. The optimum incubation temperature ranges from 15.0 to 17.5° C.

Specific gravity:

The fertilized eggs float at the water surface when its specific gravity is higher than 1.023. They sink under the middle layer when the specific gravity is lower thanl.023. The hatching rate is 80-98 % for the former case and 20-50 % for the latter. In the latter case, the larvae become abnormal and die.

Turbidity due to mud:

The effect on the hatching rates of 50 ppm silt in the water is not detectable.

However a decrease in hatching rates' is noticeable at l00 ppm.

Mechanical shocks:

It is important to avoid mechanical shocks such as disturbance and vibration, as much as possible, when gathering and transferring the eggs, Aeration is also unsuitable, unless supply is slight.

CONCLUSION

Red seabream, Pagrus major (Temminck and Schlegel, 1843) is a demersal species that occurs in the northwest Pacific (the northeastern part of the South China Sea northward towards Japan) at depths between 10 and 50 m. The red sea bream, Pagrus major (Chrysophrys major), is one of the most valuable marine fish in Japan. This is one of the fish used in aquaculture, and in India its aquaculture practice is not much developed. The seeds producing in artificial way is to be more difficult because of its less survival capacity. But in artificial way also seed produced, that is by induced method and environmental manipulation.

·